I. Introduction

Ultrasonic machining is an innovative technique that harnesses the power of high-frequency vibrations to process materials. This method stands out for its ability to machine hard, brittle, and heat-sensitive materials with remarkable precision, making it an invaluable tool in modern manufacturing.

Mastering ultrasonic machining processes is crucial for manufacturers seeking to push the boundaries of material processing. It not only expands the horizons of what’s achievable but also opens up new possibilities for product design and innovation, ensuring a competitive edge in the industry.

II. Understanding Ultrasonic Machining

Definition and Principles of Ultrasonic Machining

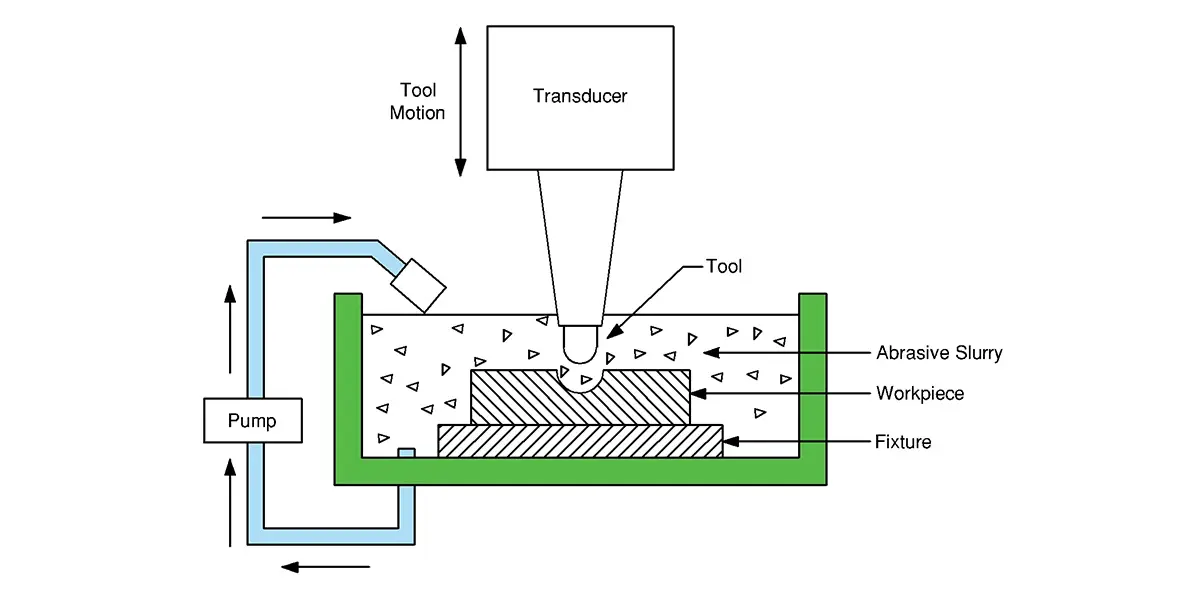

Ultrasonic machining is a machining process that utilizes high-frequency vibrations to remove material from a workpiece. The process involves using an abrasive slurry that consists of abrasive particles suspended in a liquid. This slurry is used to grind away material from the workpiece, enabling precision and accuracy in the machining process. One of the main advantages of ultrasonic machining is its ability to work with hard and brittle materials such as ceramics and composites.

Comparison with Other Machining Processes

Ultrasonic machining offers several advantages over traditional machining methods. By utilizing high-frequency vibrations, ultrasonic machining can achieve a high level of precision and surface finish. The process is non-thermal, which helps to prevent heat-induced deformations in the workpiece. Additionally, the tool wear in ultrasonic machining is relatively low, leading to longer tool life and better cost-effectiveness.

Extending the Understanding of Ultrasonic Machining

In ultrasonic machining, a vibrating tool, often referred to as a horn, transfers the ultrasonic vibrations to the abrasive particles on the workpiece. The high-frequency vibrations generated by the transducer, typically in the range of 20-50 kHz, help in the efficient removal of material. This makes ultrasonic machining suitable for machining hard materials like boron carbide and carbide, which are otherwise challenging to machine using traditional methods.

One of the key applications of ultrasonic machining is in the manufacturing of precision components for industries such as aerospace and electronics. The process requires specialized equipment and expertise to enable the efficient removal of material from the workpiece.

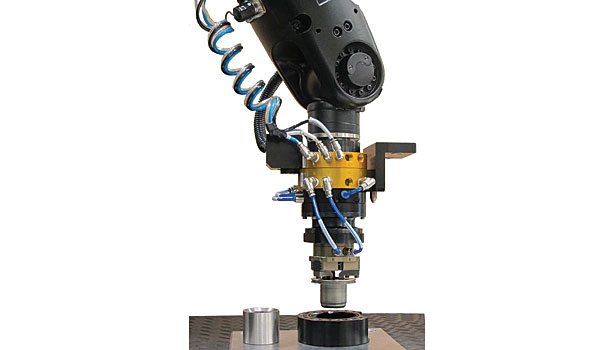

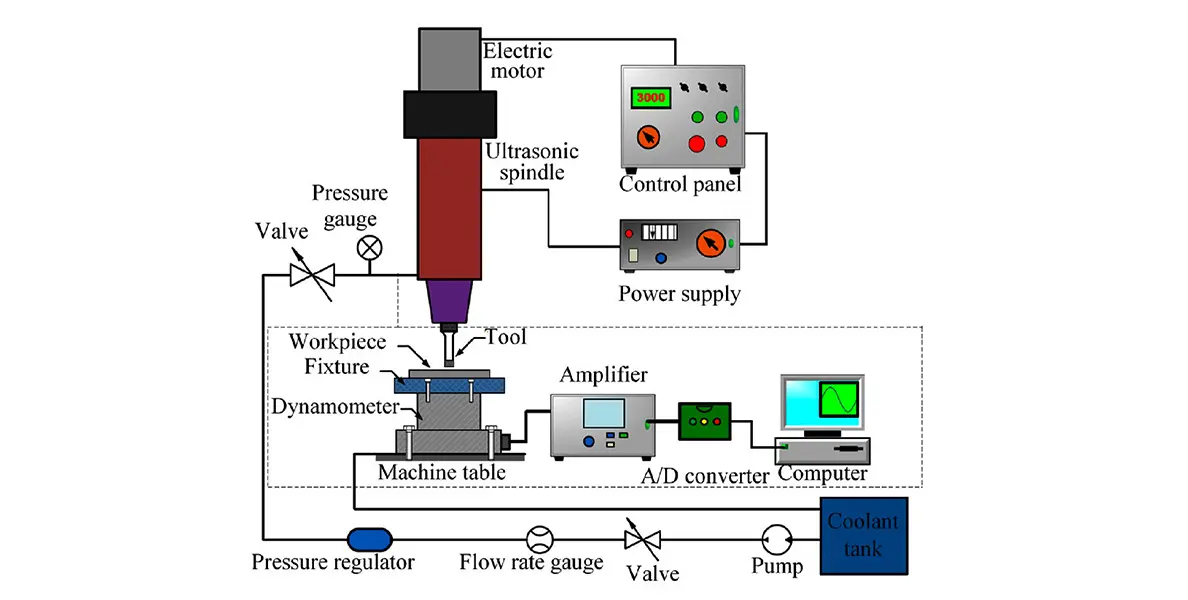

III. Components of Ultrasonic Machining System

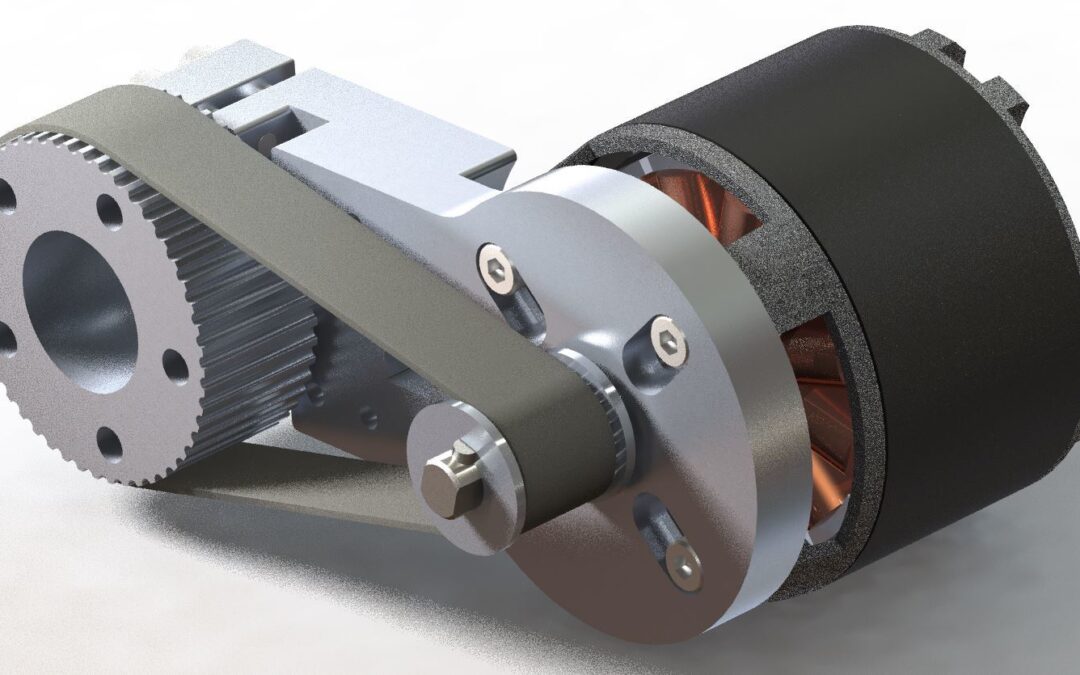

Ultrasonic Generator

The ultrasonic generator is the heart of the ultrasonic machining system. It converts electrical energy into high-frequency vibrations, setting the stage for precise material processing. This component’s reliability and performance are foundational, ensuring a consistent supply of ultrasonic energy to drive the machining process efficiently.

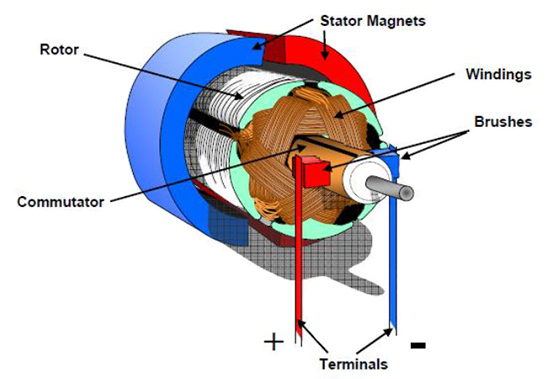

Transducer

The transducer plays a pivotal role in the system, acting as the bridge between the generator and the tool. It transforms electrical vibrations into mechanical ones, amplifying the ultrasonic frequencies to the levels needed for effective machining. The transducer’s efficiency is key to transferring energy smoothly and achieving the desired cutting action.

Booster and Horn

The booster and horn are integral components that work in harmony to amplify the ultrasonic vibrations further. The booster increases the vibrational amplitude, while the horn, or tool, focuses these vibrations onto the workpiece. This focused energy is what enables the ultrasonic machining process to shape and refine materials with exceptional accuracy and delicacy.

Tooling

Tooling in ultrasonic machining refers to the specific tools used to apply the ultrasonic vibrations to the workpiece. These tools are meticulously designed to withstand the rigors of high-frequency vibrations and to maintain their shape and size throughout the machining process. The right tooling ensures that the ultrasonic energy is effectively utilized to achieve the desired outcomes.

Workpiece

The workpiece is the material being shaped by the ultrasonic machining process. It is the end result of the combined efforts of the generator, transducer, booster, horn, and tooling. The workpiece’s preparation and presentation are crucial, as they directly affect the quality of the machining. Properly securing and positioning the workpiece ensures that the ultrasonic vibrations can act upon it uniformly, leading to precise and clean results.

IV. Mastering Ultrasonic Machining Processes

Proper set-up and alignment

Mastering ultrasonic machining begins with the proper set-up and alignment of the equipment. Ensuring that the machine components are correctly positioned and aligned is crucial for achieving optimal performance. A well-aligned system minimizes vibrations, reduces stress on the machine, and contributes to the accuracy and repeatability of the machining process. This initial step sets a solid foundation for successful ultrasonic machining.

Selection of cutting parameters

The selection of cutting parameters is a critical aspect of mastering ultrasonic machining. Choosing the right frequency, amplitude, and tool geometry for the specific workpiece material is essential. These parameters significantly influence the machining process’s efficiency and the quality of the finished product. By carefully selecting and adjusting these parameters, manufacturers can enhance material removal rates and achieve the desired surface finish with precision.

Tool maintenance

The selection of cutting parameters is a critical aspect of mastering ultrasonic machining. Choosing the right frequency, amplitude, and tool geometry for the specific workpiece material is essential. These parameters significantly influence the machining process’s efficiency and the quality of the finished product. By carefully selecting and adjusting these parameters, manufacturers can enhance material removal rates and achieve the desired surface finish with precision.

Monitoring and troubleshooting

Continuously monitoring the machining process allows for the early detection of potential issues, such as irregular vibrations or changes in tool performance. Prompt troubleshooting and addressing these issues help maintain the process’s integrity, ensuring consistent quality and avoiding costly production delays. By staying vigilant and proactive, manufacturers can achieve high levels of reliability and precision in their ultrasonic machining operations.

V. Advantages and Limitations of Ultrasonic Machining

Advantages

Ultrasonic machining offers a multitude of advantages, making it an exceptional choice for specific applications. It excels in processing hard, brittle materials that are difficult to shape with conventional methods. The non-contact nature of the process results in minimal heat generation and stress on the workpiece, thus preserving the material’s integrity.

Additionally, ultrasonic machining provides high precision and repeatability, allowing for the creation of complex geometries and fine finishes. The ability to machine materials without the need for a cutting force also means that parts with intricate designs can be produced efficiently.

Disadvantage

Despite its many advantages, ultrasonic machining also has some drawbacks. One disadvantage is the relatively slow material removal rate compared to other machining processes. The process also requires a constant supply of abrasive slurry, which adds to the operational costs.

Additionally, ultrasonic machining can be challenging to machining soft materials due to the high-frequency vibrations that are more suitable for hard and brittle materials. When comparing the advantages and disadvantages of ultrasonic machining, engineers and manufacturers need to consider the specific requirements of their machining tasks.

While ultrasonic machining offers exceptional precision and surface finish, it may not be the most efficient option for all types of materials and applications. Understanding the capabilities and limitations of ultrasonic machining is essential for mastering this advanced manufacturing process.

VI. Applications of Ultrasonic Machining

Ultrasonic machining (USM) is a non-thermal process that uses high-frequency vibrations to remove material from workpieces. This mechanically driven machining process is particularly effective for drilling holes and shaping materials made of hard substances like ceramic, quartz, silicon carbide, and metal.

A leading aerospace manufacturer leveraged ultrasonic machining to produce intricate turbine engine components from high-strength, heat-resistant superalloys. The transducer effectively converted electrical signals into precise, high-frequency vibrations, which were subsequently amplified and directed toward the workpiece.

This meticulous process ensured the creation of complex geometries with exceptional surface finishes, all without the thermal damage typically associated with traditional machining methods. As a result, the company was able to enhance component performance, durability, and reliability, solidifying its position at the forefront of aerospace innovation.

Some challenges faced by USM include tool wear rates and the ability to drill deep holes without damage. Solutions to these challenges have involved the development of new materials removal processes and the use of advanced electrochemical techniques to improve efficiency.

VII. Factors Affecting Ultrasonic Machining

Frequency

The frequency of ultrasonic machining is a critical factor that influences the process’s efficiency and the quality of the finish on the workpiece. Operating at high frequencies, typically in the range of 20 kHz to 40 kHz, ultrasonic machining optimizes material removal rates for specific applications. Higher frequencies provide finer finishing touches, while lower frequencies are better suited for deeper penetration and material removal.

Amplitude

Amplitude directly impacts the intensity of the vibrations in ultrasonic machining, and, consequently, the rate at which material is removed. Greater amplitudes enhance the process’s effectiveness, particularly when working with harder materials. However, it’s essential to balance amplitude with the workpiece’s material properties to prevent damage or excessive stress.

Tool material

The tool material must be capable of withstanding the rigors of high-frequency vibrations in ultrasonic machining. Therefore, tool materials should be tough and wear-resistant to maintain their shape and effectiveness over time. Advances in tool material technology have led to the use of specialized alloys and ceramics that improve the machining process’s durability and efficiency.

Workpiece material

Different materials respond differently to the ultrasonic vibrations, affecting the machining process’s success. Hard, brittle materials that are difficult to machine with conventional methods are often well-suited to ultrasonic machining, which can achieve precise cuts without inducing crack propagation.

Tool geometry

Tool geometry in ultrasonic machining is designed to optimize the distribution of ultrasonic energy to the workpiece. The shape and size of the tool influence the machining process’s efficiency and the final product’s quality. Proper tool geometry ensures that the energy is focused and effective, leading to cleaner cuts and smoother surfaces on the workpiece. Designers carefully consider the tool’s geometry to match the specific requirements of each machining task.

VIII. Conclusion

Ultrasonic machining, with its unique advantages, has been adeptly applied across industries. It offers precision cutting for hard and brittle materials, showcasing its versatility and reliability in manufacturing.

Mastering ultrasonic machining is vital for industries seeking to innovate and excel. It empowers manufacturers to tackle complex designs and materials, ensuring a competitive edge in today’s rapidly evolving market landscape.

FAQs

1. How does ultrasonic machining achieve better results compared to other machining techniques?

Ultrasonic machining utilizes liquid as a medium to transmit vibrations, leading to effective material removal with minimal thermal effects. This results in improved surface finish and overall machining efficiency.

2. What are the key benefits of ultrasonic machining in the manufacturing industry?

Ultrasonic machining offers advantages such as precise material removal, the ability to machine complex shapes, extended tool life, and improved surface finish. It is especially beneficial for ceramics and hard-to-machine materials due to its non-thermal nature.

3. Can Ultrasonic Machining produce complex shapes?

Yes, it can create intricate and complex shapes with high-quality surface finishes, making it suitable for components requiring tight tolerances.

4. How does ultrasonic machining contribute to enhancing the efficiency of manufacturing processes?

Ultrasonic machining enhances efficiency by enabling precise, heat-free material removal for hard and brittle materials, reducing tool wear, and improving part quality.

5. Is Ultrasonic Machining environmentally friendly?

Yes, it is considered environmentally friendly as it does not produce harmful byproducts and is a cleaner process compared to some traditional machining methods.

References

1. The basic principles and characteristics of ultrasonic processing – Baidu Wenku. (n.d.). https://wenku.baidu.com/view/a378a8415b1b6bd97f192279168884868762b88a.html

2. Principles of Ultrasonic Processing – Baidu. (n.d.). https://wenku.baidu.com/view/b50dc6c4cb50ad02de80d4d8d15abe23492f036a.html

3. Brief description of ultrasonic machining process characteristics and applications – Baidu Wenku. (n.d.). https://wenku.baidu.com/view/60a0d871b62acfc789eb172ded630b1c59ee9b88.html?_wkts_=1719469957126

4. The basic principle and characteristics of ultrasonic machining_Machine tool business network. (n.d.). https://www.jc35.com/tech_news/detail/64308.html