Plasma frequently appears as a fighting superpower in video games and comic books. This is due to pragmatic considerations that plasma cutting technology has been applied on a large scale in industry. Sit tight and hold on while I introduce you to the principles and types of plasma cutting.

What is CNC plasma cutting and how it works

Before I start a further intro about the various types of plasma cutting, I need to ensure you, our esteemed reader, know how it works. I’ll use simple words to describe how it works and the main components that help it work.

Description of plasma cutting process

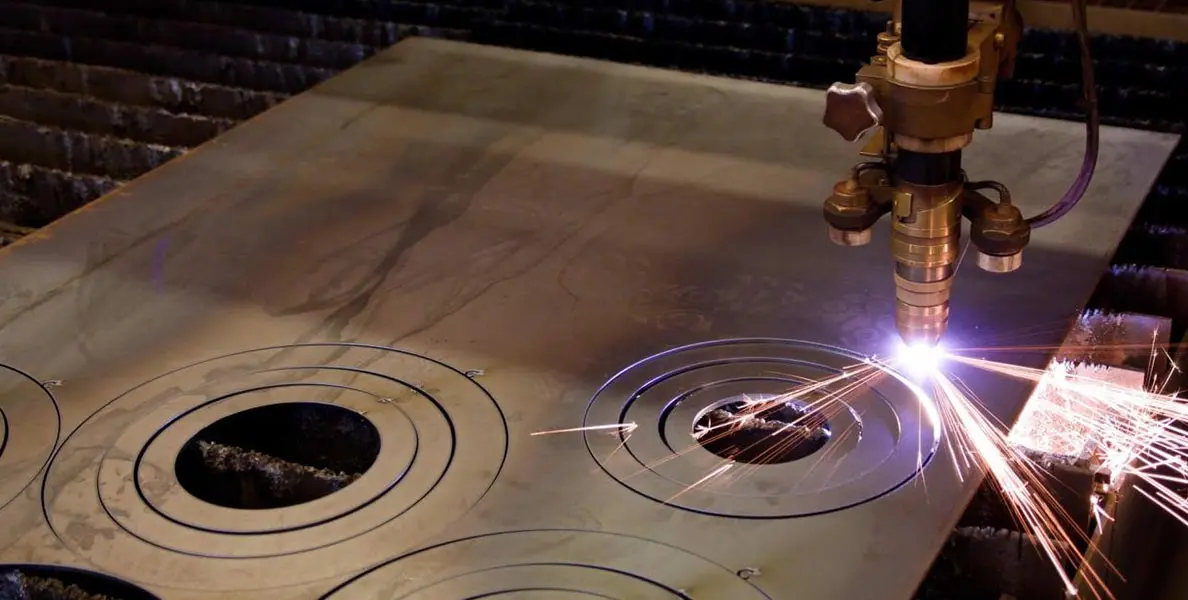

The plasma cutting process is a widely used method for cutting through electrically conductive materials such as steel, aluminum, brass, and copper.

The working process involves:

1. Use computer-aided design (CAD) software and computer numerical control (CNC) system to create codes that direct the plasma torch along a programmed cutting path.

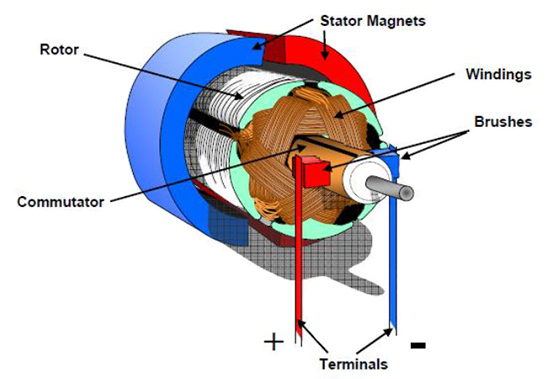

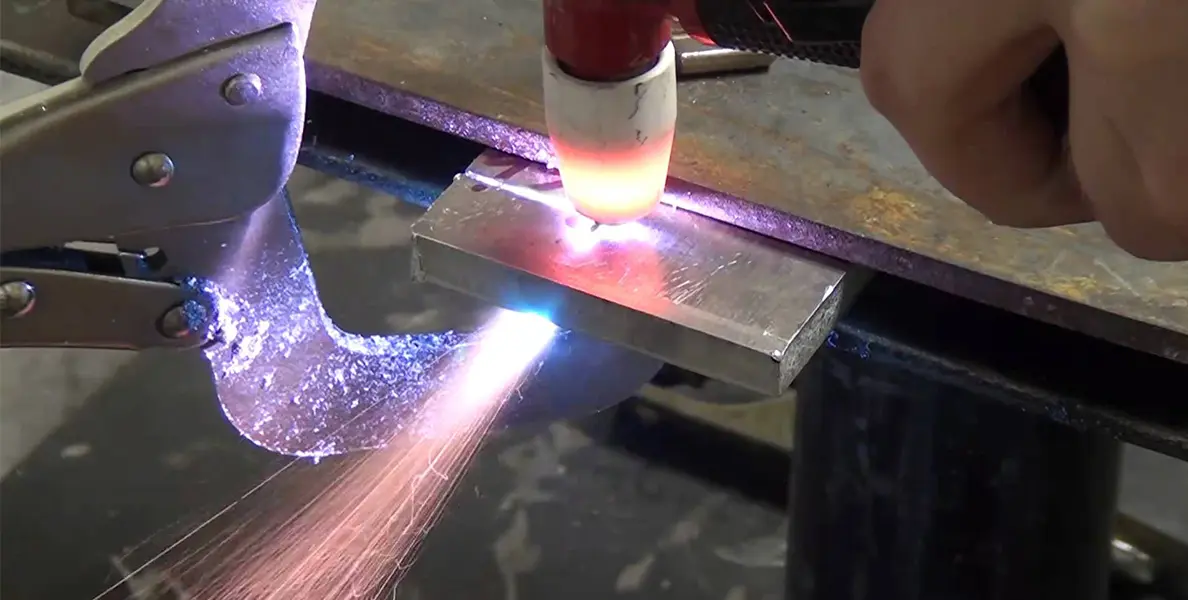

2. Use of a high-velocity jet of ionized gas, typically compressed air, which is passed through a small nozzle. The electrical arc of the nozzle raises the temperature of the gas to 30,000 degrees Fahrenheit and transforms it into plasma.

3. This superheated plasma is then directed at the material being cut, melting it and blowing away the molten metal with the force of the gas stream.

4. The gas stream will create an electrical circuit through the workpiece and the nozzle. The arc ionizes the gas passing through the nozzle, turning it into plasma.

5. The plasma then cuts through the material with extreme precision and speed.

During the process, The operator can adjust the speed of the cutting process and the intensity of the plasma beam to achieve the desired results.

Components of a CNC plasma cutting system

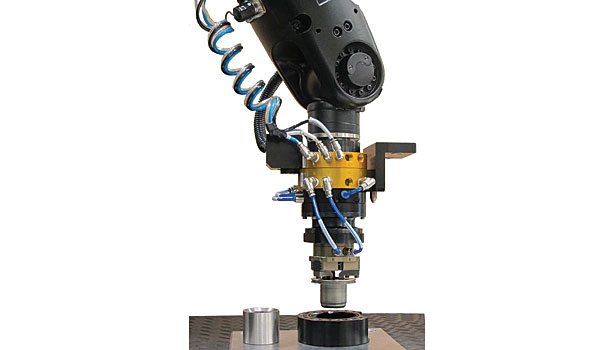

A plasma cutting system consists of several key components that work together to accurately and efficiently cut through various materials.

| Component | Effect |

| Controller | Allowing operators to input codes and commands as parameters to control the entire process |

| Cutter | using a high-velocity stream of ionized gas and a high-powered plasma arc to melt the material to the desired shape |

| CNC plasma cutting table | provides a stable surface for the material, ensures accurate and precise |

| Torch height controller | maintain the optimal height and distance between the tool and the material |

| Smoke extraction system |

Release smoke and ensure fire safety |

| water table | For cooling in the process |

| software | For designing and programming codes for cutting |

Types of CNC plasma cutting machines

Okay, I believe our esteemed reader already understands how plasma cutting works and why it can cut metal. Now I’m gonna introduce you to three main plasma cutters, their respective working principles, pros, cons, applications, and what materials are used for cutting.

Benchtop CNC plasma cutters

Benchtop cutters involve using a CNC system to guide the tool along the computer-designed cutting path to create precise and clean cuts with minimal material wastage.

| Benchtop CNC cutters |

| Advantages | Disadvantages |

| High precision and speed | Strict size and variety limit |

| Ease-using | Not suitable for larger scale projects or thick material |

| Short setup and transport time | High initial cost |

| Suitable Material | Steel, Aluminum, Copper, Wood, Plastic |

| Application Area | Small Fabrication shops, Educational institutions, Hobbyist workshops |

| Product Example | Custom Artwork, Prototypes, Signage, Machinery Parts |

Portable CNC plasma cutters

Portable CNC cutters involve using computer codes to guide a high-temperature torch along and cut through the sheet, which makes clean and accurate cuts with high precision.

| Portable CNC cutters |

| Advantages | Disadvantages |

| Transport flexibility | Small capacity limit |

| High speed with low heat generate | Not suitable in large metal pieces |

| Cost-effectiveness | The high requirement in setup and training |

| Suitable Material | Steel, Stainless Steel and Aluminum |

| Application Area | Metal fabrication process, Automotive Manufacturing, Construction |

| Product Example | Custom parts, Signage, Prototypes |

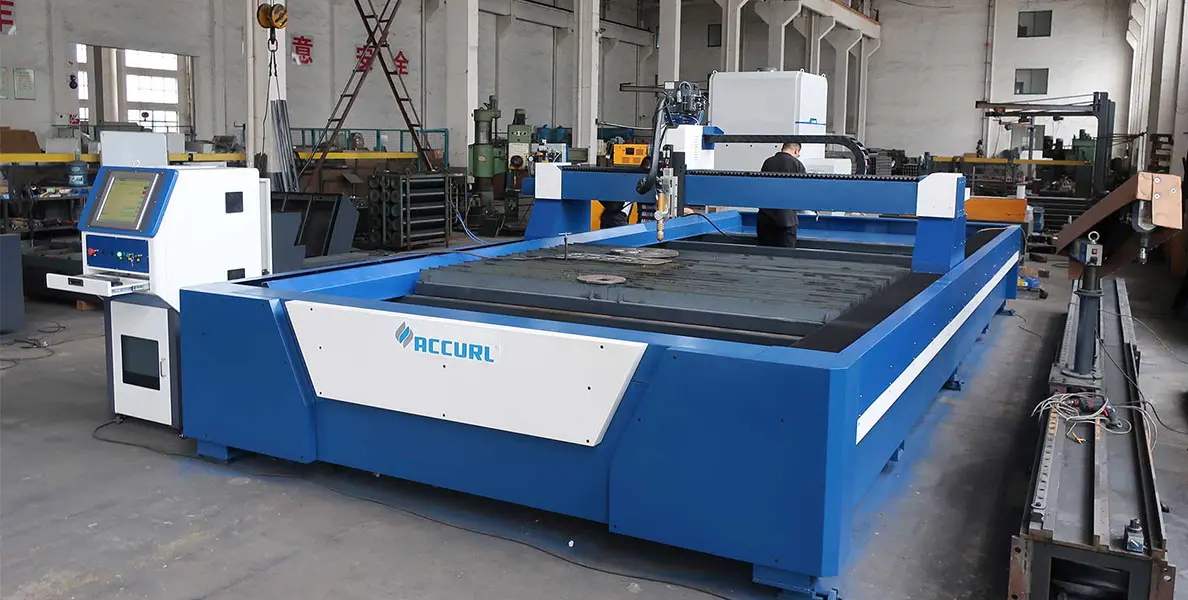

Industrial CNC plasma cutters

Industrial CNC cutters involve programming wanted patterns, dimensions and shapes, and cutting steel, aluminum, copper, and stainless steel accurately following the code.

| Industrial CNC cutters |

| Advantages | Disadvantages | |

| Suitable in cutting through thick materials | High initial cost | |

| Ideal for large-scale production | High requirements in setup and training | |

| Excellent production continuity | Can only cut conductive materials |

| Suitable Material | Steel, Aluminum, Stainless Steel, Copper |

| Application Area | Manufacturing, Construction, Automotive |

| Product Example | Simple shape for Prototype, Intricate designs for Decorative metalwork |

Conclusion

Sum it up

- CNC plasma cutting offers a cost-effective and versatile solution for cutting various materials and is famous for its speed, precision, and versatility.

- This technology has three main segment types: Benchtop, Portable, and Industrial. Each one has its benefits and limitations.

- By understanding the key points and best practices associated with this technology, users can maximize efficiency and accuracy in their cutting processes.

The future outlook of plasma cutting

- With the progress of hardware and software, plasma cutting will become faster and more accurate, which eventually leads to cost savings and increased productivity.

- Also, we believe this technology will continue to advance and evolve to become a user-friendly service with lower prices and accessible to a wider range of businesses.

XMAKE and CNC plasma cutting

As the leading manufacturing platform, XMAKE has rich experience in dealing with manufacturing needs and difficulties. If you are looking for plasma cutting solutions or other CNC processes, the best way to let a smile come back to your face is to leave it to XMAKE.

Frequently Asked Questions:

Q1: How does the cutter create plasma during the work?

A: A plasma tool operates by forcing a gas through a narrow nozzle and at the same time sending an electric arc through the gas. This process creates plasma, which is a state of matter where some of the electrons are separated from their atoms.

Q2: What is the difference between plasma cutting and flame cutting?

A: Plasma cutting is a thermal cutting process that uses a focused jet of hot plasma to cut through materials, while flame cutting uses a combination of oxygen and fuel gas to create a high-temperature flame for cutting. Plasma cutting is often more precise and efficient than flame cutting.

Q3: How important is the CNC software in plasma cutting?

A: CNC software plays a crucial role in plasma cutting as it allows users to program and control the cutting process with precision. The software translates design files into cutting instructions for the CNC machine, ensuring accurate and efficient cutting operations

Q4: Can plasma cutters cut through thick metal?

A: Yes, plasma cutters can cut it through various thicknesses, ranging from thin sheet metal to thick stainless steel, aluminum, and even high-definition plasma cuts on specialized machines.

Q5: What is the difference between CNC plasma cutting and laser cutting?

A: While both processes use a high-energy source to cut materials, CNC plasma cutting uses a plasma torch to cut through metal, whereas laser cutting systems utilize a laser beam for cutting purposes.

Q6: What is CNC control in plasma cutting?

A: CNC control in plasma cutting refers to the use of computer numerical control technology to precisely guide the plasma torch along the programmed cutting path, ensuring accurate and repeatable cuts.

Q7: Can handheld plasma cutters be used for CNC cutting?

A: Yes, handheld plasma cutters can be used for CNC cutting applications when mounted on a CNC table or gantry, allowing for automated cutting processes and increased productivity.

References

- The development trend of CNC plasma cutting technology in my country | Xuanbang Cutting Machine. (n.d.).http://www.sunbow-cut-weld.com.cn/article.asp?id=641

-

Leo, G. (2023c, December 12). Plasma Cutting: Definition, Process and Benefits. Aria | Online Manufacturing for On-Demand Custom Services.https://www.madearia.com/zh-CN/blog/plasma-cutting-definition-process-and-advantages/

- Application of CNC plasma cutting machine in cutting plate | CNC plasma cutting machine | CNC flame cutting machine | CNC cutting machine | Gantry type CNC flame plasma cutting machine manufacturer – Wuhan Huayucheng CNC. (n.d.). http://www.6188cnc.com/news/content-960.html