Introduction

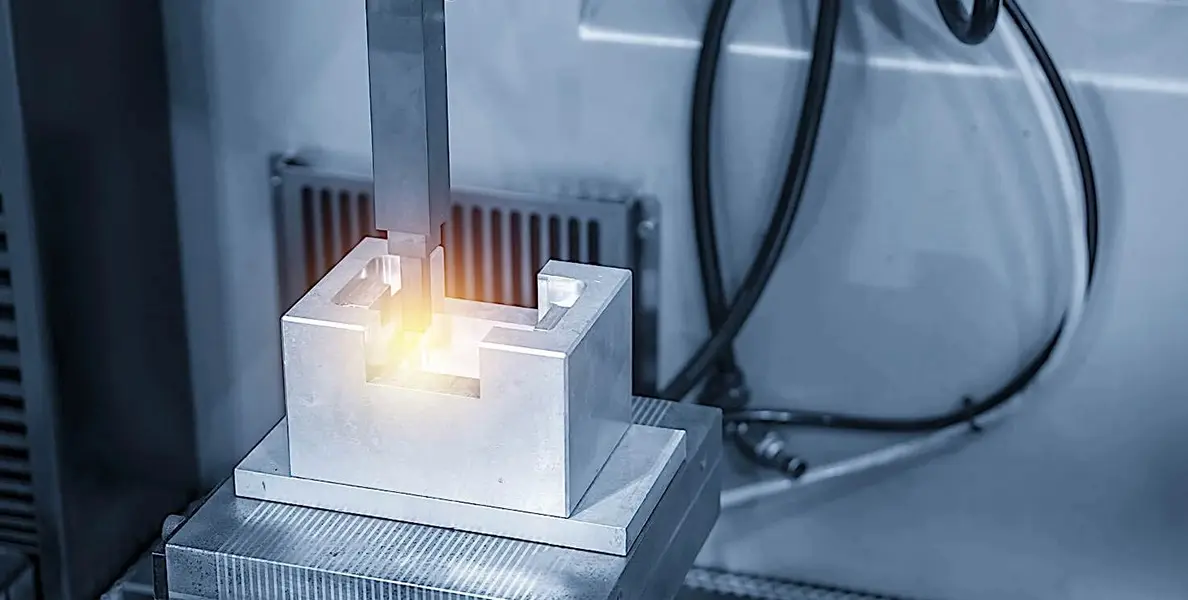

Realizing the differences between wire EDM and sinker EDM machining methods is more important than ever as industries like aerospace and medical device making need more and more complex parts. In precision production, let us look at the different features and uses that make EDM and WEDM stand out.

What is Sinker EDM machining?

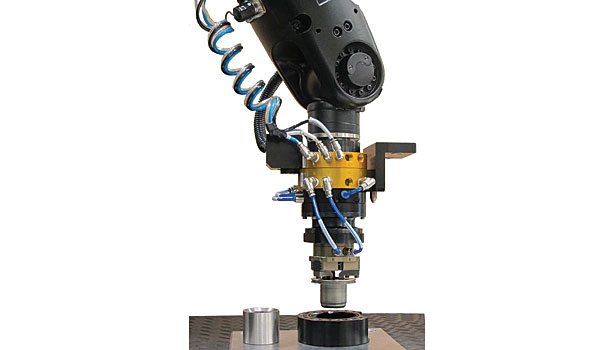

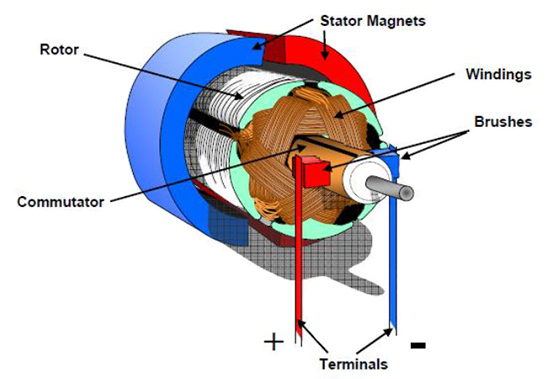

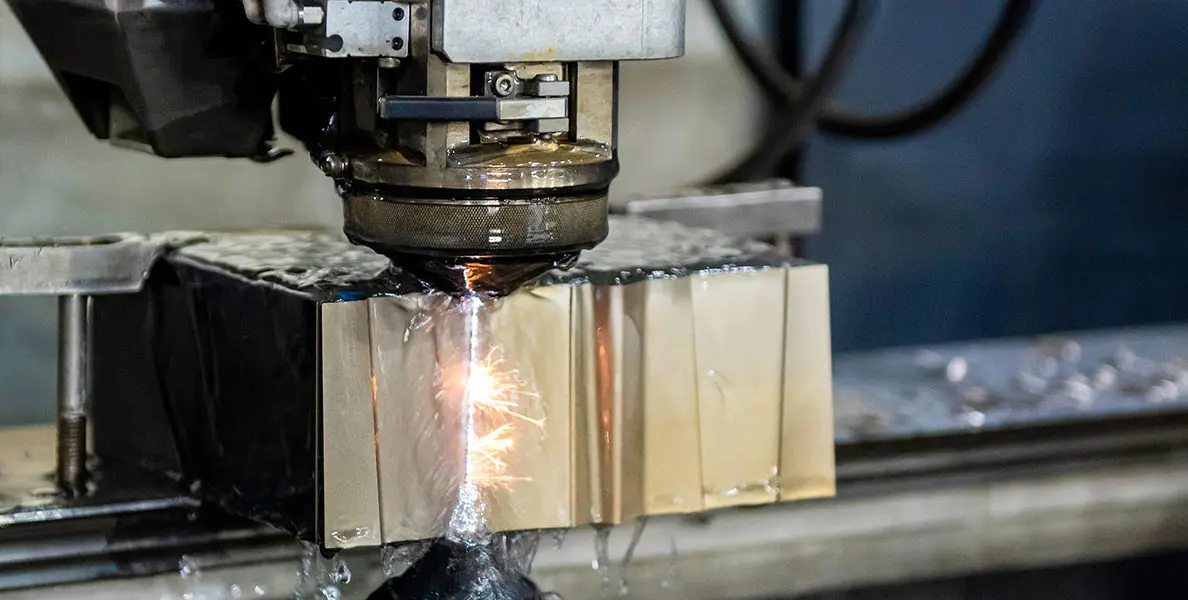

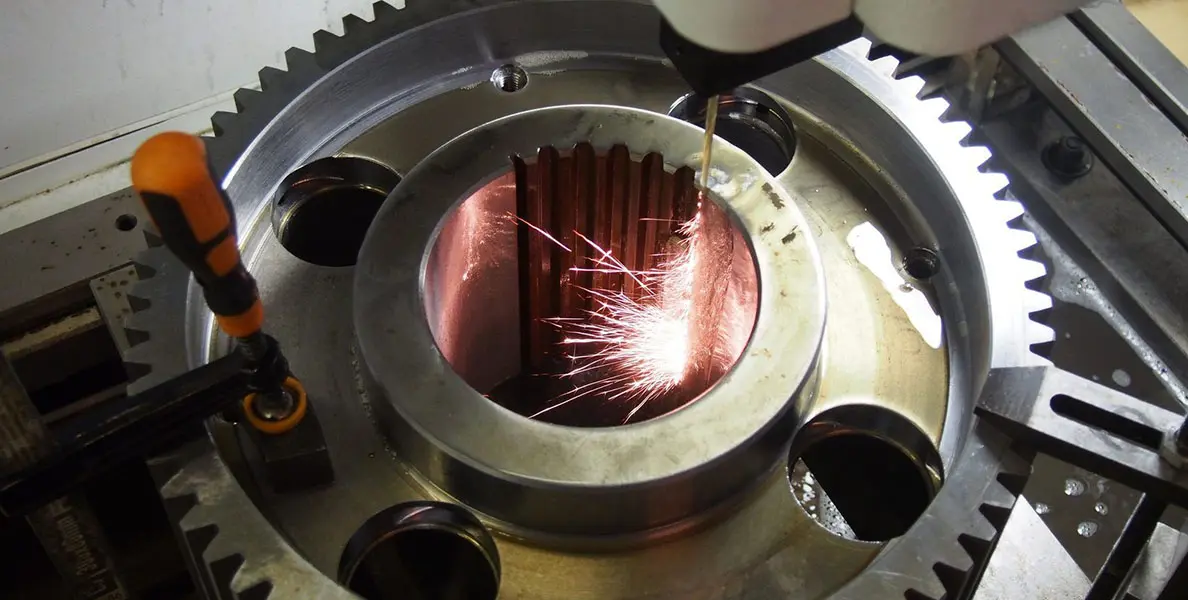

Sinker EDM, also known as Ram EDM or Die Sinker EDM, employs electrical discharges to erode material from a workpiece. EDM is typically ideal for cutting precise forms and geometries in conductive materials including steel, copper, and graphite. The procedure uses a graphite or copper electrode near the workpiece submerged in a dielectric fluid. Sparks from high voltage remove material from the workpiece, allowing the electrode to sink and shape it. Sinker EDM is reliable, can machine hard materials, and can create parts with complicated cavities or undercuts that other technologies cannot.

What is wire EDM machining?

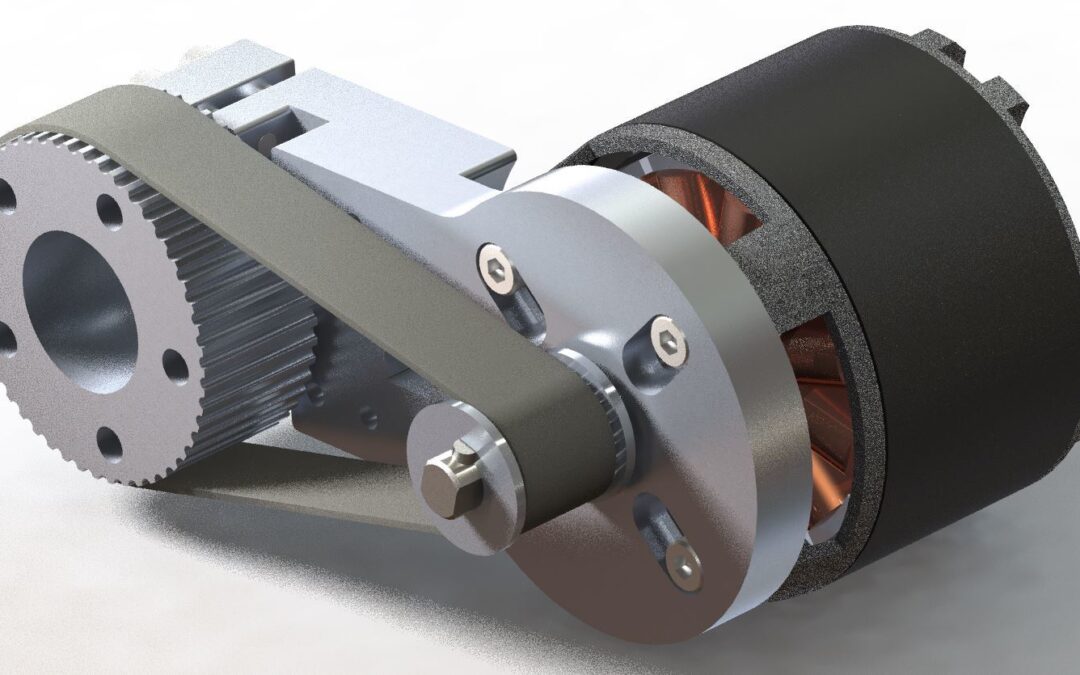

Wire-cut EDM, or Wire Electrical Discharge Machining, is a precision machining technique that uses a continuously fed, thin wire electrode to cut through materials. It’s capable of handling a variety of conductive materials, from steel and copper to superalloys. Known for its accuracy and ability to create complex shapes, Wire EDM is prized in industries demanding high precision. However, it does have limitations, such as slower cutting speeds for hard materials and the need for post-process refinement. This technology shines where traditional machining falls short, making it ideal for intricate parts and molds.

Difference between Sinker EDM and wire EDM machining

| Criteria | EDM Machining | Wire EDM Machining |

|---|---|---|

| Process | Uses electrical discharges between electrode and workpiece | Utilizes a continuously fed thin wire as the electrode |

| Speed and Accuracy | Generally slower due to spark generation and electrode wear. The accuracy is 1μm. | Faster for intricate parts; offers high accuracy with minimal wear. The accuracy can reach 0.001mm. |

| Cost-effectiveness | Can be more cost-effective for simple shapes due to less material removal | May have higher setup costs but is efficient for complex shapes and hard materials |

| Complexity of Shapes | Capable of creating complex shapes but limited by electrode design | Excellent for complex and intricate shapes due to the wire’s flexibility |

| Features and Capabilities | Good for machining hard materials, can use different electrode shapes | Specializes in detailed and intricate cuts, no physical contact with a workpiece |

| Limitation | Limited by the size and shape of the electrode, may require multiple setups | Slower for large workpieces and less effective for very deep or wide cuts |

How to choose the right machining process: sinker EDM VS. wire cut EDM?

Material Types and Thicknesses

Sinker EDM, with its ability to use shaped electrodes, is excellent for machining thicker, denser materials like hardened steel.

Wire Cut EDM, on the other hand, shines with thinner materials and intricate designs, making it ideal for detailed parts and complex geometries.

Required Tolerances

Wire Cut EDM offers ultra-precision, delivering tight tolerances and smooth finishes, perfect for parts needing high accuracy.

Sinker EDM, while also precise, maybe more suited for parts with looser tolerances due to its method of material removal.

Prototyping vs. Production Needs

For prototyping and creating one-off parts, Sinker EDM’s capacity to machine complex shapes with a single electrode makes it highly advantageous.

Conversely, Wire Cut EDM’s efficiency in cutting multiple parts from a single block of material makes it superior for production runs, offering consistency and repeatability.

Budget Considerations

Wire Cut EDM may have lower setup costs for simple designs, but Sinker EDM can be more cost-effective for complex parts due to its ability to machine as-is without the need for intricate wire paths.

Weighing the initial costs against the per-part cost over the production run will guide your decision for the most economical approach.

Case studies and examples

Application of Sinker EDM Machining

Sinker EDM machining is widely used in the manufacturing industry, especially for parts with complex shapes or high dimensional accuracy. For example, in the automotive industry, Sinker EDM is used to manufacture high-precision engine parts and transmission components. In the mold manufacturing field, it can process complex cavities and cores, which improves the accuracy and service life of molds.

An automotive parts manufacturer used Sinker EDM to produce 10,000 high-precision engine valve seats. By using Sinker EDM, the company realized a 50 percent increase in productivity and a 30 percent improvement in part dimensional accuracy. This improvement not only increased engine performance and reliability but also reduced costs by minimizing material waste and increasing productivity.

Sinker EDM in modern manufacturing not only helps companies to improve product quality and reduce production costs but also realize more efficient production. By precisely controlling the discharge process, Sinker EDM can machine complex shapes that are difficult to achieve with traditional methods, revolutionizing the manufacturing industry.

Application of Wire EDM Machining

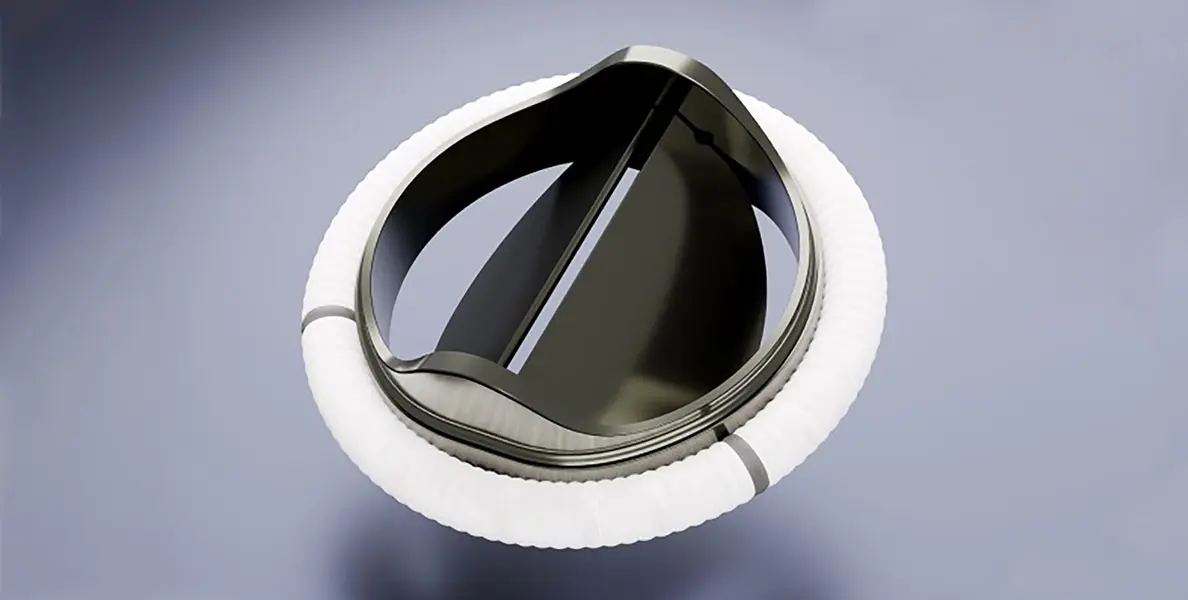

Metals that are hard to work with can be easily cut with Wire EDM cutting, which is known for its accuracy. It is used a lot in many fields, like electronics to make exact circuit breakers, aerospace to make complicated parts and medicine to make complicated prosthetics and surgical tools.

Take the example of a medical device business that used Wire Cut EDM to make 20,000 tiny heart valve parts. They were able to achieve an amazing accuracy of ±5 microns by using this technology. This made sure that the parts fit perfectly inside the valves. This accurate production cut the time needed for fitting the heart valves by 20% and made them last 15% longer, showing how important Wire Cut EDM is to progressing medical technology.

Conclusion

By looking at the differences between sinker EDM and wire EDM machining, it is clear that even though they are both non-traditional machining methods, they are used for different things. Wire EDM cuts through the piece of work with a thin wire, while sinker EDM wears away the material with an electrode. This is a very important difference to keep in mind when choosing the right cutting method for a job. You can also call EDM “electric discharge machining.” This method is more precise and accurate than other ways of making things. We can expect EDM and wire EDM technology to get better and move forward as technology does.

FAQs

1. What is the typical surface finish quality after Sinker EDM machining?

Sinker EDM can provide a good surface finish quality, typically in the range of Ra 0.2 to 1.0 μm, depending on the material and settings.

2. What is the typical tolerance range for Wire EDM machining?

Wire EDM can achieve very tight tolerances, typically within ±0.005 mm (±0.0002 inches).

3. Can Wire EDM produce parts with complex 3D geometries?

While Wire EDM is primarily used for prismatic shapes, it can produce parts with some 3D geometries by tilting the wire electrode or using multi-axis machines.

4. How does Wire EDM compare to laser cutting in terms of precision?

Wire EDM offers higher precision than laser cutting, especially for small and intricate parts, due to its ability to control the spark gap and cut path with high accuracy.

5. How does the EDM machine work?

EDM machines utilize electrical discharges to shape or manipulate a workpiece. They are commonly used in traditional machining processes.

6. Can you explain the wire and the workpiece in wire EDM?

In the wire EDM process, a wire is used as an electrode to cut through the workpiece accurately, leaving a clean and precise finish.

7. How does hole drilling EDM differ from other EDM processes?

Compared to other machining, drilling EDM focuses on creating holes in workpieces using electrical discharges. It is a specific type of EDM process that caters to non-traditional machining needs.

References

1. Anderson, S. (2024, June 14). What is Electrical Discharge Machining (EDM). Proleantech | Custom Parts On-Demand Manufacturing. https://proleantech.com/zh-CN/discovering-the-world-of-edm-what-is-electrical-discharge-machining/

2. Richards, A. (2024b, June 23). Explore the key differences between wire EDM and EDM sinker machining technologies. Proleantech | Custom Parts On-Demand Manufacturing. https://proleantech.com/zh-CN/differences-between-wire-and-sinker-edm/

3. What is the difference between EDM and Wire EDM? _Wire Cutting_Electrode_Mold. (n.d.). Copyright © 2017 Sohu.com Inc. All Rights Reserved. https://www.sohu.com/a/571399226_120645396