SLA 3D Printing Service

- ZLive Project Tracking

- ZGet Parts in Days

- ZQuick Delivery of Intricate Designs

-

All uploads are secure and confidential.

All uploads are secure and confidential.

What is SLA 3D Printing?

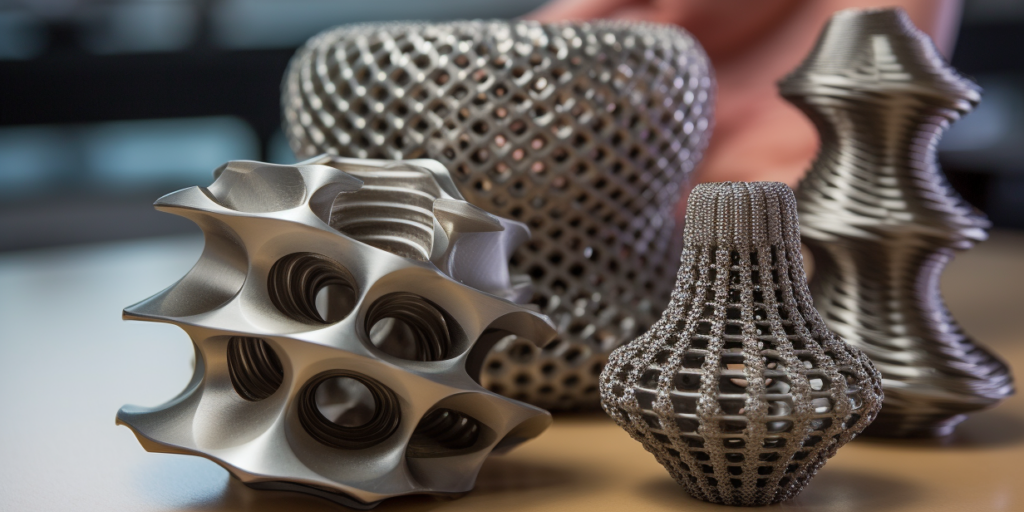

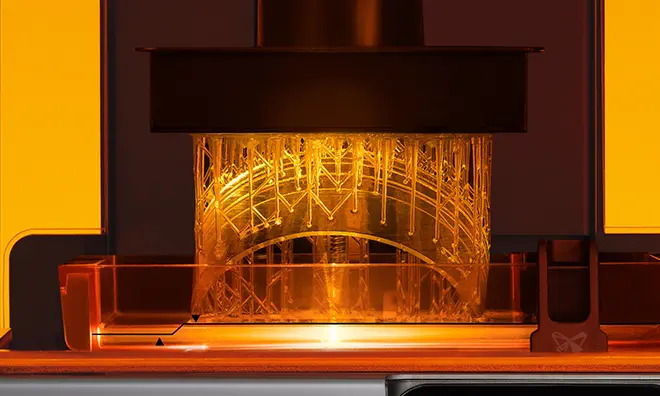

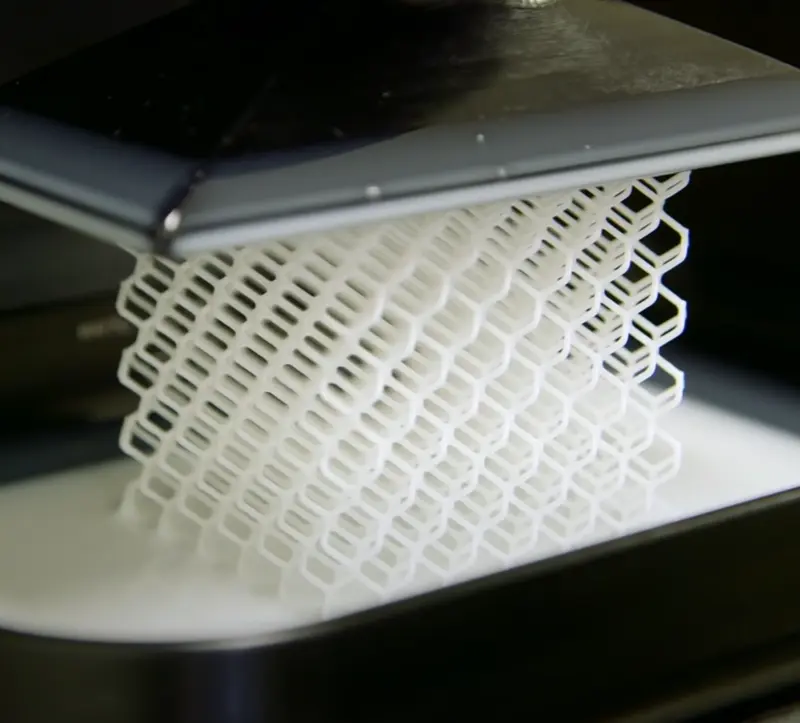

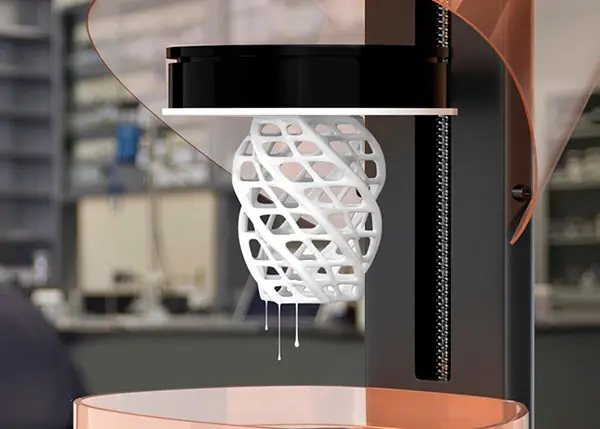

SLA (Stereolithography) 3D printing is an additive manufacturing technology that uses a UV laser to cure and solidify liquid photopolymer resin into solid layers with precision. The process begins with a platform that is submerged in a vat of liquid resin. A UV laser traces a cross-section of the object on the resin’s surface, hardening the material. Once one layer is cured, the platform lowers, and the next layer is drawn, bonding to the previous one. This layer-by-layer process continues until the entire object is formed.

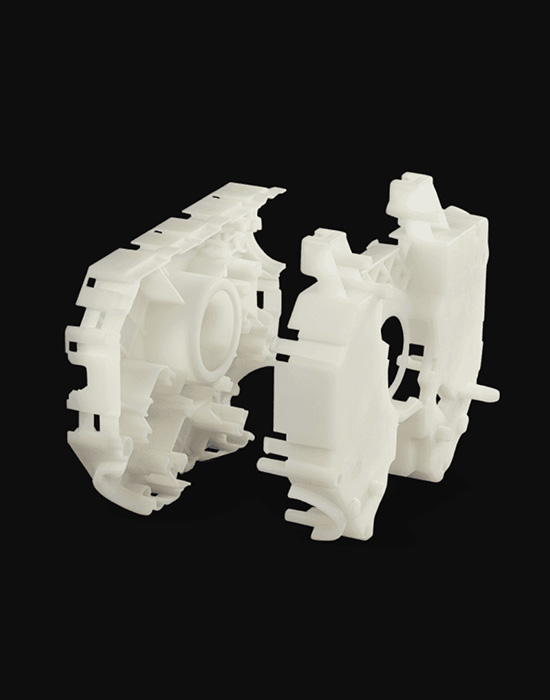

SLA 3D printing is renowned for producing highly accurate and detailed parts with smooth surface finishes, making it suitable for applications that require fine details, such as jewelry, dental models, and high-quality prototypes. It also enables the creation of complex geometries that might be difficult to achieve with other manufacturing methods.

SLA 3D Printing Materials Selection

Accura 25

Accura 25 is a durable and flexible SLA 3D printing material, ideal for snap-fit designs, master patterns for urethane casting, and conceptual models. Accura 25 can also be easily primed and painted post-printing.

Accura 60

Accura 60 is ideal for transparent parts, offering high tensile strength suitable for complex functional assemblies. However, its low-temperature limit should be considered for high-heat applications.

Accura AMX Rigid black

A highly accurate resin, known for its excellent stiffness and smooth surface finish, making it perfect for creating detailed industrial prototypes and robust components.

Accura ABS Black

It offers high strength, impact resistance, and a smooth surface finish, making it ideal for functional prototypes, end-use parts, and components that require both toughness and detail.

Accura ClearVue

Accura ClearVue is a translucent material that balances aesthetic and physical properties effectively. When paired with a Clear Coat, it achieves the highest transparency among our materials.

Accura Xtreme Grey or White 200

SLA Accura Xtreme Grey is a durable 3D printing material designed to resist breakage, making it suitable for demanding assembly applications and vacuum-casting master patterns.

Somos Evolve

Somos Evolve is a photopolymer resin used in Stereolithography (SLA) 3D printing technology. It is renowned for its high-temperature resistance and strong mechanical properties.

Somos Waterclear

This resin is specifically engineered for transparent applications, offering exceptional optical clarity and high light transmission, making it ideal for applications where visibility and light passing through the material are crucial.

- We can source any other material on request, but quotes take up to 48 hours.

Surface Finish Options for Stereolithography

Description

Advantages

Application Areas

Standard Finish

Basic sanding and polishing to remove support marks.

Cost-effective, quick turnaround.

Prototyping, fit testing, visual models.

Polished

Additional polishing for a smooth, glossy surface.

High aesthetic appeal, reduced layer lines.

Consumer products, cosmetic prototypes.

Primed and Painted

Surface is primed and painted after smoothing, for color and texture finish.

Custom colors, high-quality finish.

Display models, prototypes, marketing samples.

Matte Finish

Sanding or media blasting to reduce shine and smooth out surfaces.

Reduces layer visibility, non-reflective surface.

Visual models, prototypes, art pieces.

Clear or Translucent

Special resins and post-processing to achieve transparency or translucency.

Optical clarity, aesthetic versatility.

Lenses, light guides, medical models.

UV-Cured Coating

UV-resistant coating applied to enhance durability and reduce discoloration.

Increased durability, longer lifespan.

Outdoor applications, durable prototypes.

*Note: This table outlines general 3D printing surface finish options. Actual preparation methods vary and may necessitate specific technical expertise and equipment. For personalized advice on the optimal surface finish for your project, please get in touch.

SLA 3D Printing General Tolerances

Feature Type

General Tolerance

Description

Dimensional Accuracy

±0.1% (minimum ±0.3 mm)

The overall accuracy of the part dimensions, depending on the size and geometry of the model.

Hole Diameter

±0.1 mm (for diameters < 5 mm)

Accuracy of holes, especially for small diameters, can vary slightly due to resin shrinkage.

Flatness

±0.3 mm per 100 mm

Tolerance for flat surfaces, which may exhibit slight warping depending on the design and resin.

Linear Dimensions

± 0.1% (with a minimum of ± 0.1 mm)

Applies to overall dimensions; may vary based on part size and geometry.

Wall Thickness

± 0.2 mm

Thinner walls may be prone to warping or breakage.

Feature Resolution

0.025 mm (Z)

High-resolution capability, especially for intricate details.

Part Warping

±0.1% (based on overall part size)

Potential deviation due to resin shrinkage or curing, affecting large or flat areas.

*Note: The table serves as a guide. Outcomes vary by material, complexity, equipment, workload, and project specifics.

Benefits of SLA 3D Printing at XMAKE

High Precision and Detail

SLA offers exceptional accuracy, capable of producing intricate designs with fine details and smooth surfaces, making it ideal for complex models.

Smooth Surface Finish

SLA prints have a naturally smooth surface finish, reducing the need for extensive post-processing and making them suitable for visual prototypes and display models.

Versatile Material Options

SLA supports a wide range of resins, including transparent, flexible, and biocompatible materials, allowing for diverse applications in various industries.

Complex Geometries

The process allows for the creation of complex and intricate geometries that might be challenging or impossible with traditional manufacturing methods.

Good Dimensional Accuracy

SLA provides consistent dimensional accuracy, ensuring that parts meet tight tolerances and fit together precisely in assemblies.

Rapid Prototyping

SLA is ideal for creating prototypes quickly, enabling fast iterations during the design and development process.

How does SLA 3D Printing Work?

SLA (Stereolithography) 3D printing uses a UV laser to cure liquid resin into solid layers. A platform is submerged in a vat of resin, and the UV laser traces each layer of the object, hardening the resin as it goes. The platform then lowers, and the process repeats layer by layer until the object is complete.

After printing, the object is removed, cleaned, and may undergo additional UV curing. SLA is known for producing highly detailed parts with smooth surfaces, ideal for precision applications.

Why Choose XMAKE’s Custom SLA 3D Printing Services

High-Precision Complex Designs

XMAKE’s SLA technology allows for the creation of detailed geometries with remarkable accuracy, making it perfect for complex designs, prototypes, and production components.

Efficient and Scalable Production

Extensive Customer Assistance

SLA 3D Printing FAQs

1. How durable and strong are the parts made with SLA 3D printing?

The durability and strength of SLA-printed parts are highly dependent on the material used and the printing process parameters. Many resins offer excellent mechanical properties suitable for functional parts and end-use applications, although they may not match the strength of some traditional engineering materials.

2. How does SLA compare to other 3D printing technologies like FDM or SLS?

While FDM (Fused Deposition Modeling) is more accessible and cost-effective for larger parts, SLA offers superior surface finish and detail. SLS (Selective Laser Sintering), on the other hand, does not require support structures and is better suited for functional parts, but SLA typically provides higher resolution and smoother finishes.

3. What post-processing steps are required after SLA printing?

After printing, parts usually require cleaning to remove excess resin and may need to be cured under UV light to enhance their mechanical properties. Additional finishing processes, such as sanding or painting, may also be applied depending on the desired final appearance.

4. What is the typical lead time for SLA 3D printing projects?

Lead times can vary based on the complexity of the design, material selection, and post-processing requirements. However, SLA is generally faster than traditional manufacturing methods, allowing for rapid prototyping and quicker iterations.

5. Is SLA printing suitable for functional prototypes?

While SLA can produce highly detailed prototypes, its brittleness may limit its suitability for functional applications. It is often used for visual prototypes rather than parts that will undergo significant stress or mechanical loading.

6. What Are Some Common Applications for SLA 3D Printing?

SLA 3D printing is widely used in various industries for applications such as rapid prototyping, manufacturing of complex parts in automotive and aerospace, dental and medical device production, jewelry design, and the creation of highly detailed models for architecture and art.

Looking for Online SLA 3D Printing Services?

-

All uploads are secure and confidential.

All uploads are secure and confidential.

Learn More about SLA 3D Printing Resources

Can You 3D Print Metal?

Can you 3D print metal? Explore the materials, methods, pros and cons, and home vs. industrial options for metal 3D printing. Learn which metals work best and how to get started.

Tin Metal: Definition, Composition, Alloys and Uses

Explore the properties, composition, and uses of tin metal and tin bronze, including QSn6‑6‑3, and learn how these materials are ideal for durable, CNC-machined components.

Understanding Anodized Aluminum

Discover how anodized aluminum enhances durability, corrosion resistance & aesthetics. Learn types, uses & limitations. Expert insights from xmake.

All About Austenitic Stainless Steel

Learn the properties, grades, applications, and benefits of austenitic stainless steel, especially 300 series, and how Xmake’s CNC services deliver precision parts.

What Is Brass Made Of: A Comprehensive Guide!

Brass is a metal alloy mainly made of copper (55–95%) and zinc (5–45%), with minor elements added to enhance its properties and versatility.

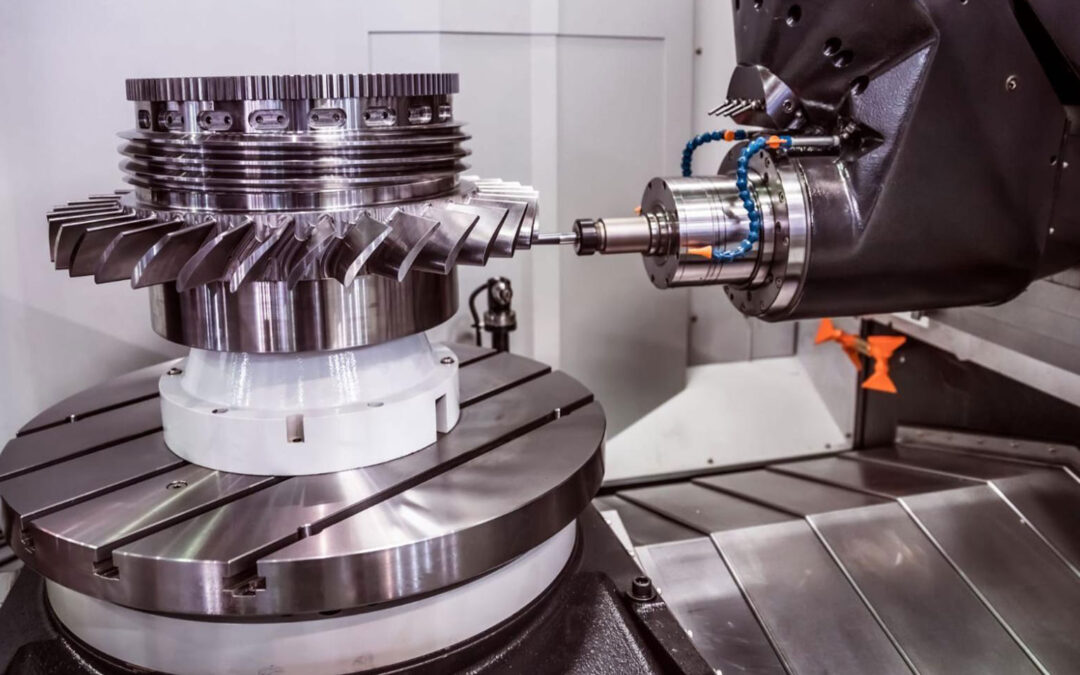

What is CNC Milling: An Ultimate Guide!

Explore what CNC milling is, how a CNC mill works, and key features of a milling machine with CNC control in this complete guide.

How to Choose Reliable CNC Machining Services?

Learn how to choose CNC machining services wisely. Compare equipment, certifications, precision & materials for optimal results. Get quality parts on time.

Resin vs Plastic: Here is the Difference

Wondering is resin plastic? Learn the key differences between resin and plastic, their uses, and when to choose each for your projects.

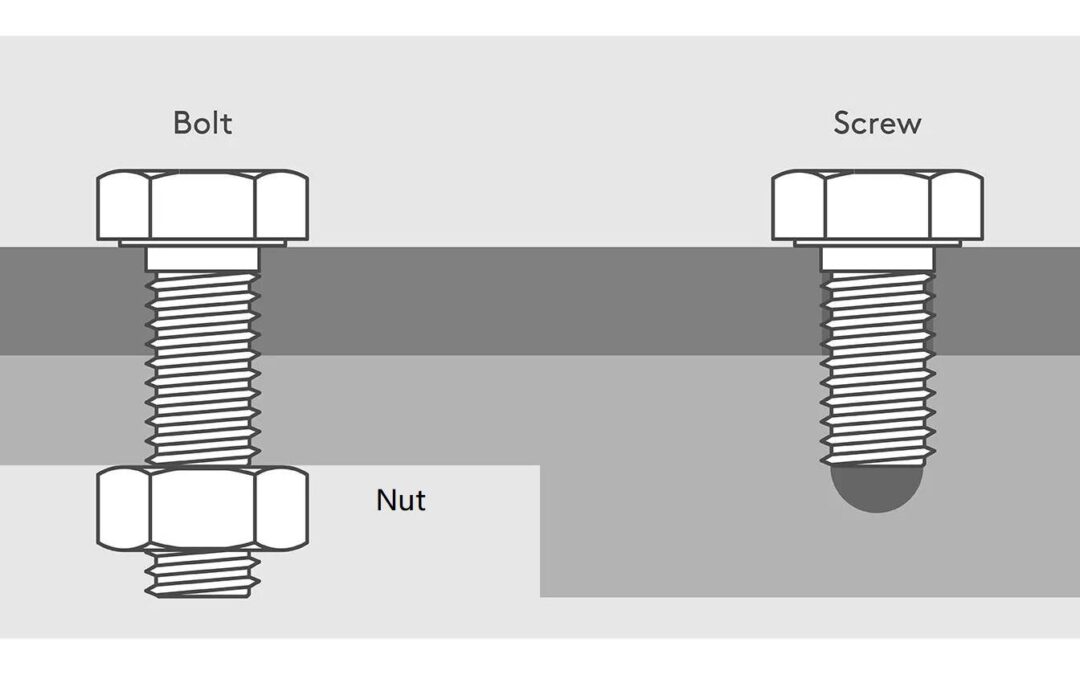

Nut vs Bolt: What is the Difference?

Explore the essential differences in nut vs bolt, including their types, materials, and best applications. Learn how to choose and maintain the right fasteners for your needs.

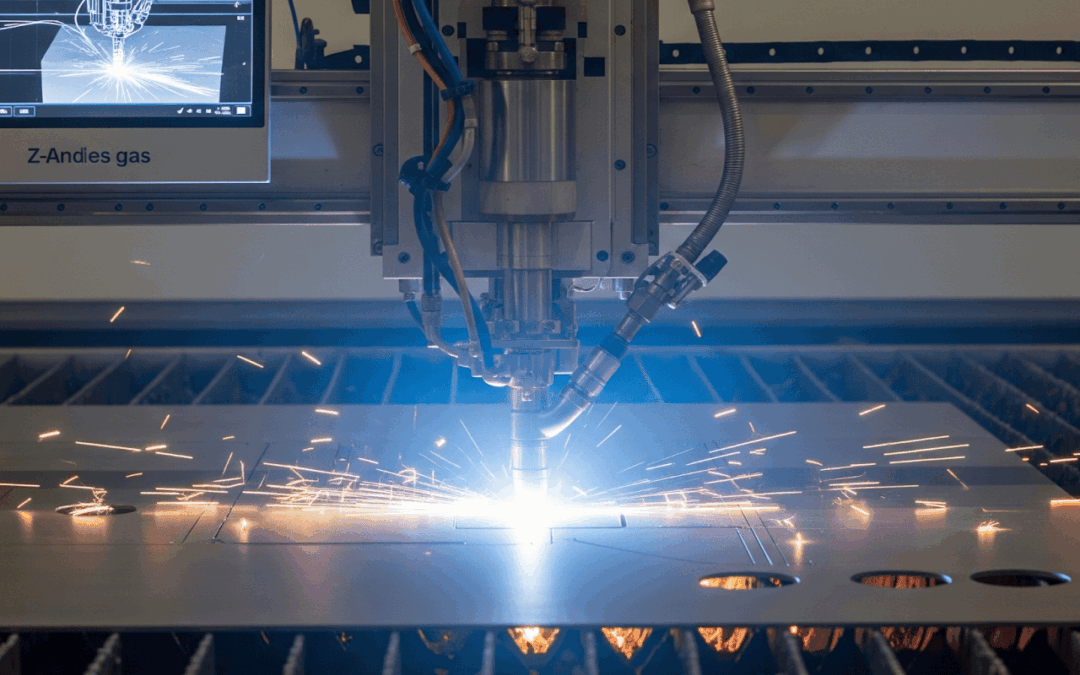

CNC Plasma Cutter: How It Works, Benefits & Selection Tips

Explore how a CNC Plasma Cutter cuts metal with precision. Learn key benefits, speed, thickness capacity, tolerance and how to choose the right system.